-

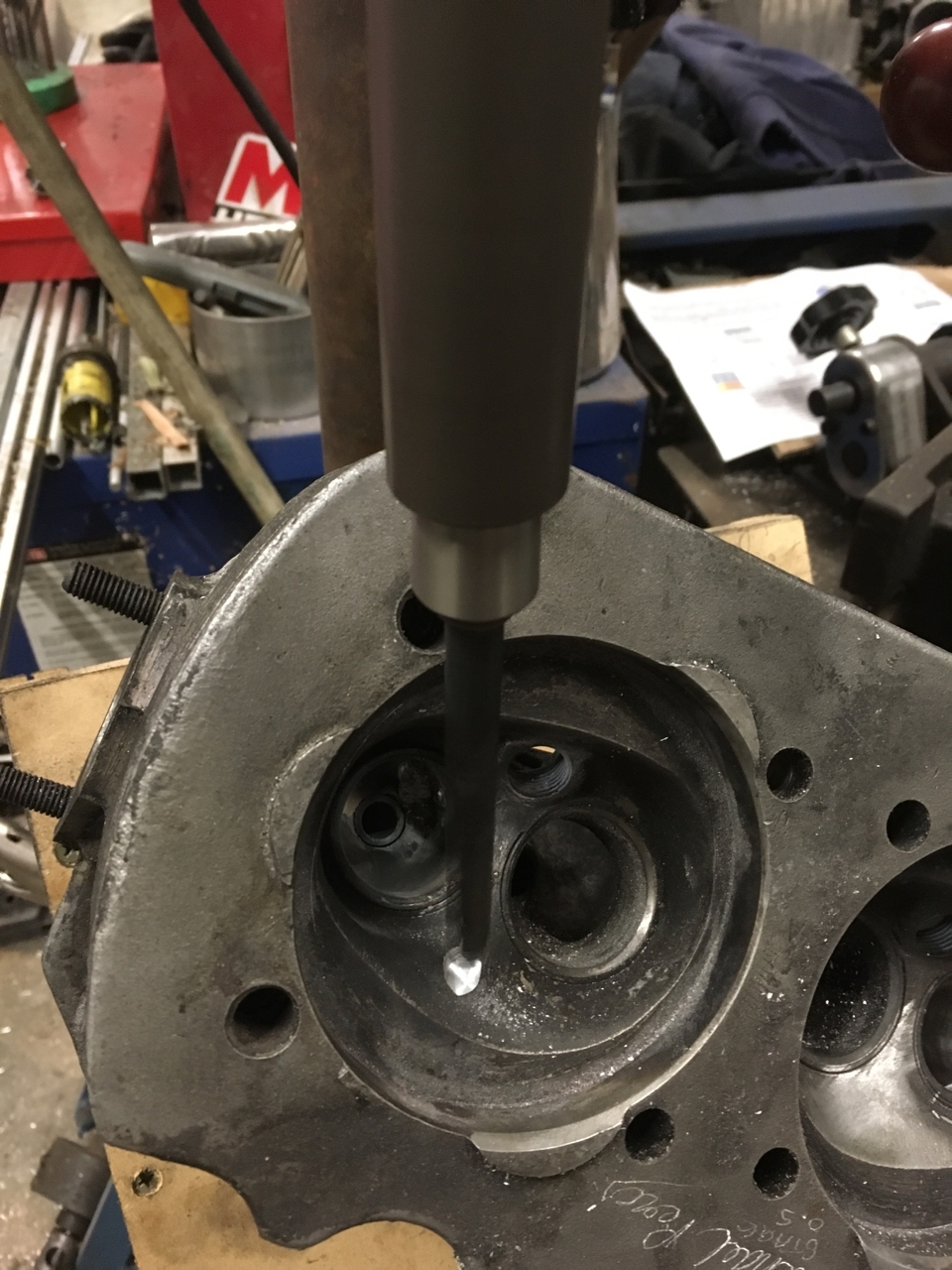

Spent a bit of time out in the workshop today. I fly-cut the other head and cut in the Singh grooves using a modified file. I previously used a Dremel but the slots were not uniform so I heated up and bent a triangular file and used that instead. The finish is much better now and it is much easier to align the slots so that they point directly at the spark plug.

I also drilled the holes for a second set of plugs. I did this on a scrap head just in case, but they went in really easy. The main purpose of the exercise was to make sure that the alignment was good and that the spark plugs cleared the push rod tubes. All I need to do now is to counter bore the holes from the opposite side to form the seat for the spark plug. I also need to get hold of a set of 10mm spark plugs to test everything out with.

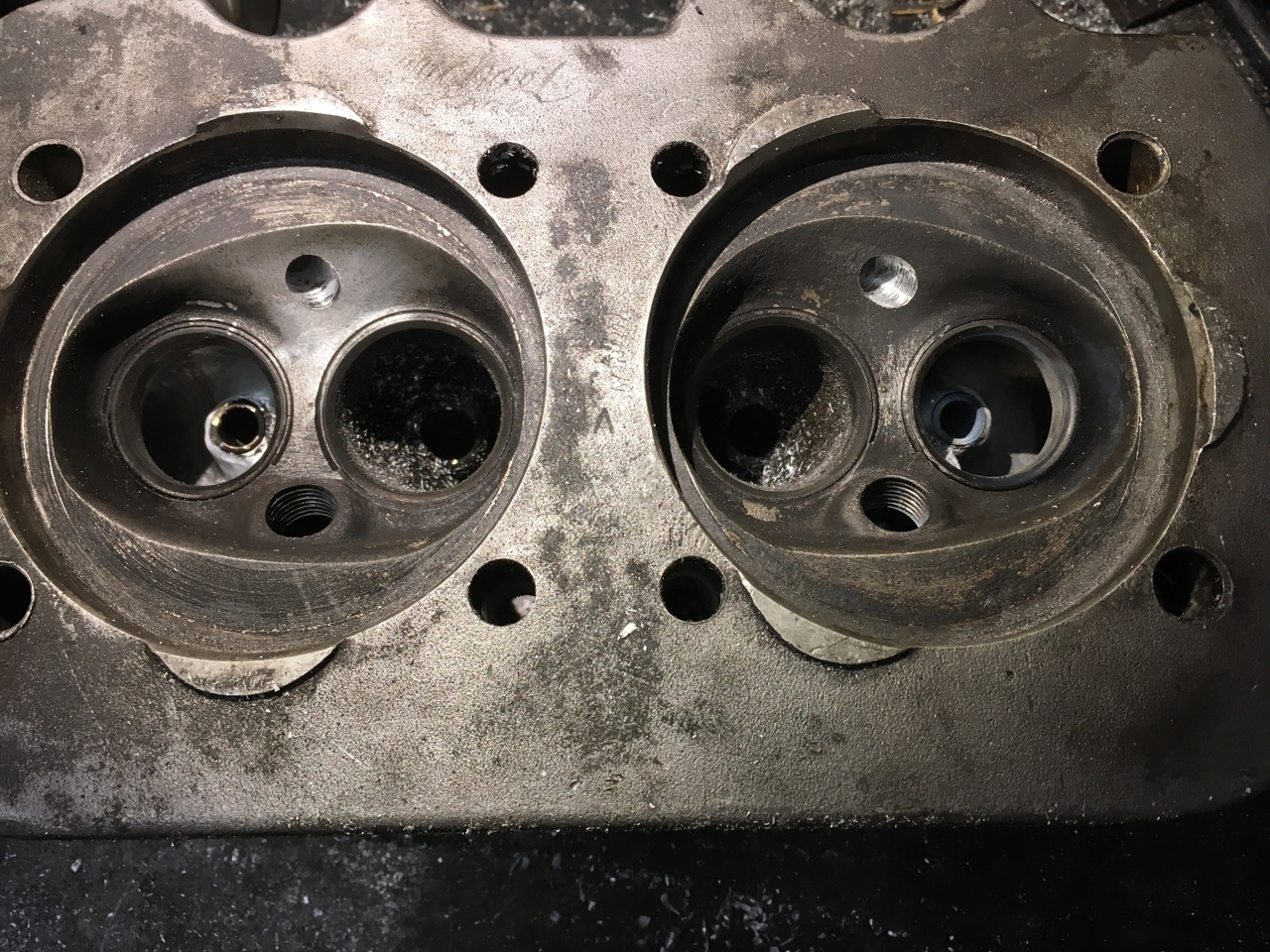

I cleaned up my new heads today to discover that one head had cracks. Could have sworn that they weren't there when I bought them. Guess I did not check close enough. At any rate, one head was okay. I'll pair this with the one head that I have that is also okay. Only issue is one is a type 3 and one is a bug head which means the inlet ports are massively different. Nothing that a little time with the Dremel cannot fix. Managed to get one port done, will do the other tomorrow.Post is under moderationStream item published successfully. Item will now be visible on your stream.