-

So a few steps forwards followed by a few steps backwards. Picked up some stainless valves and a 69mm counterweighted crank at the weekend. My valve seat cutters arrived and I finished porting the heads so was pretty much on track for finishing off the heads this weekend. That was until I noticed that there were cracks in the exhaust chamber bowls. Hadn't noticed this before as the bowls were pretty dirty and it is not an area that needs material removed so they only showed up after I gave the ports a bit of a sand and polish.

Not put off I decided to try and weld the ports, I prepped the outside of the crack and managed to get some beads laid down but just could not get a bead to take inside the port. After a few attempts I gave up.

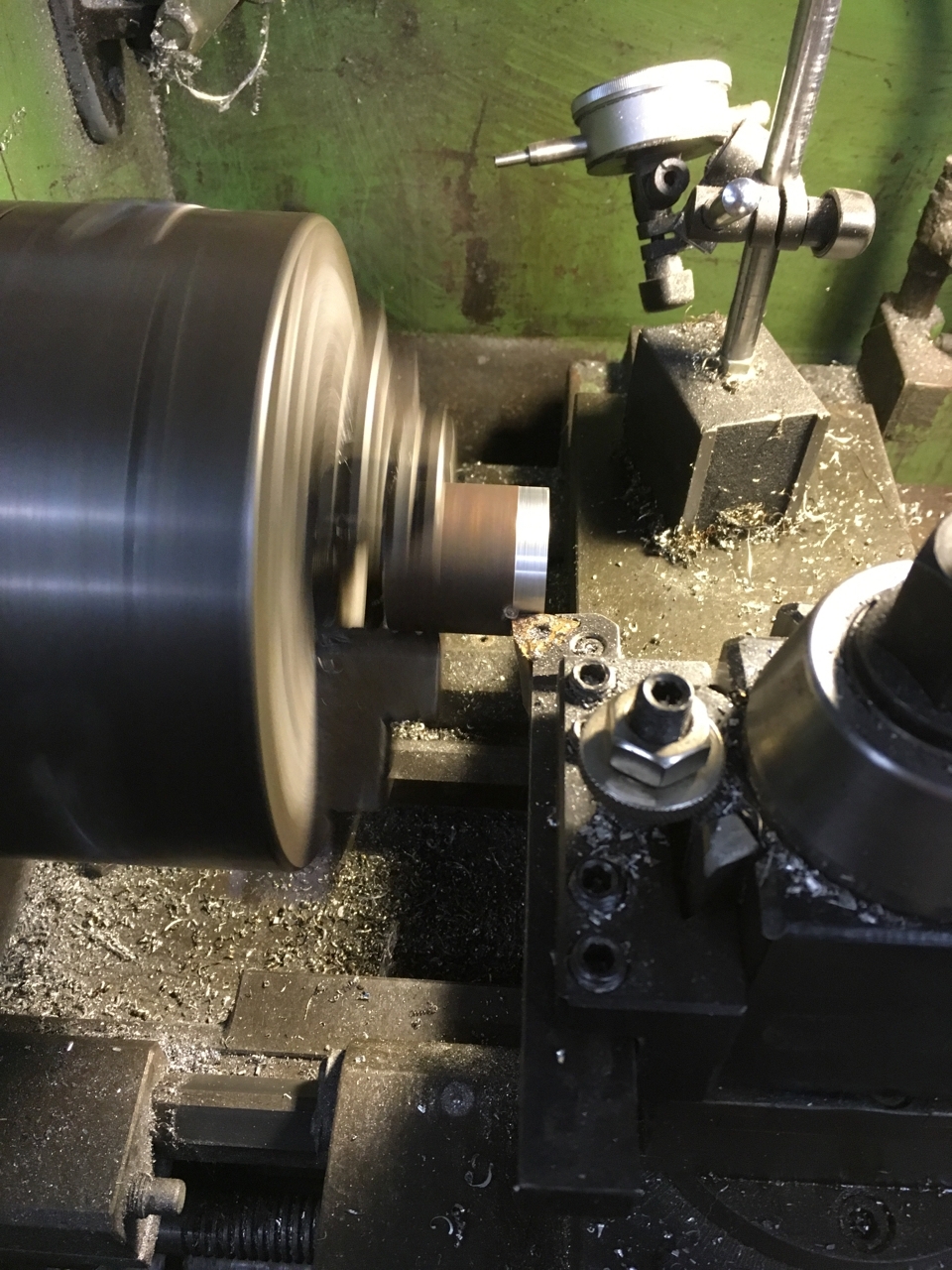

I ended up moving on to another spare pair of heads that I had (the test heads) figuring that I could simply replace the recessed exhaust seats once the porting was finished. So I ported these and researched removing and fitting exhaust seats. In the process I discovered that the seats are made from a variety of materials including 4140. As I had some 4140 I decided to make up my own ports. All I need to do not is fit them.

Something else I decided to have a go at is making my own flow bench. I didn't get too far but did manage to make a pressure take off point from an old spark plug - basically remove the insides and then tap for 3/4" NPT and fit a barbed fitting. Still left to do is make the manometer and a calibration plate to allow me to be able to map the characteristics of the bench which will allow me to read in CFM. Will be interesting to see what these heads flow.

Post is under moderationStream item published successfully. Item will now be visible on your stream.